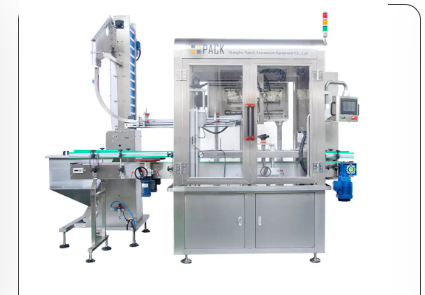

Efficiency and precision are critical in producing syrup-based products. A good syrup filling machine will be designed so exactly that it meets these requirements time and time again. Let us see what makes it so functional and some of the reasons include technological upgrades and the design which is specific according to the properties of syrup.

High Precision Filling

When beerigan syrup bottles are being filled, accurate fills are essential for product quality and to comply with labeling rules. CapacitySyland SL Single head volumetric semi automatic syrup filling machines delivers 50 fills per minute;Semi automatic fully automatic syrup filling machinesSyland SL volumetric 1 liter semi automatic syrup filling machine neck and product container;AccuracySyland SL Single head volumetric syrup filling machines has an accuracy of +/- 1% or depending on the machine design and the syrup some special type +0.5 %accuracy if viscosity of the syrup & machine design is suitable to this syrup. By employing these superior pumping and metering systems, volume of syrup per container can be perfectly calibrated.

Speed and Efficiency

Being able to fill many bottles in a very short time is very convenient. Current syrup filling machines can fill 10-100 bottles per minute. This high throughput is essential to meet consumer demand and make the production time as efficient as possible especially during the peak production cycles.

Adaptability to Viscosity

Syrup is an extremely viscous product and this provides unique challenges for filling equipment. This uniquely specialised nozzle and positive displacement pump technology has been proven to perform flawlessly on the high viscosity liquids such as syrup with no clogging, dripping or fluctuating volumes. This flexibility, in turn, assures a constant and reliable operation of the plant, even when processing foamy or adhesive syrups.

Versatile Container Handling

A well-functioning machine can handle different types of containers (sizes and shapes), which gives you the freedom of product packaging. Quick,simple, resettable rail and filling head changes for different sizes and shapes of bottles from small cough syrup type bottles to large bulk syrup bottles. For manufacturers who have multiple product lines to offer, that versatility is crucial.

Hygienic Design

When it comes to consumable products it is most important to maintain hygiene during production. They are made from stainless steel, making them easy to clean and resistant to residues building up. Additionally, most of these machines have self-cleaning mechanisms that sanitize the insides of the pathways after every batch so that the impact of the pathogens in the air is minimized.

Durability and Reliability

Syrup filling machines must be robustly built to survive the harsh conditions associated with frequent industrial use. This will help minimise breakdowns and provide longevity to the unit, ensuring years of trouble free service as a result of the high quality materials and components.

Ease of Maintenance

Simplicity in maintenance not only increases the additional life of the machine but also reduces downtime. Simple routine maintenance with low maintenance requirements like changing seals or cleaning nozzles is made easy based on accessible components and less need for tools for syrup filling machines.

Production Line Compatibility

At last but not the least, a proficient syrup filling machine seamlessly synchronizes with any existing production lines, such as cappers, labelers, and packaging stations. Its integrated nature ensures an efficient operation with less likelihood of bottlenecks and improved overall line efficiency.

A syrup filling machine is a critical part of the modern-day production line in the food and pharmaceutical industries and these features in totality determine the efficiency of such a unit. Manufacturers can be more productive, deliver on the highest quality standards, and adjust to market demands more quickly with the right machine in place.