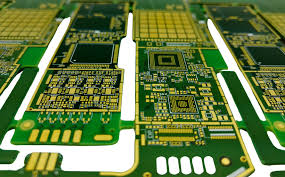

One of the materials that is most known in the electronics industry is FR4, which is highly demanded in the manufacturing of printed circuit board (PCB). In this article, we cover the wide range of high-priority applications and the benefits of FR4 material for numerous industries.

Superb Electrical Insulator

The typical feature of FR4 material is its excellent electrical insulation properties. Thousands of woven fiberglass cloth with an epoxy resin binder], it is inherently flame-resistant and dielectric. With a dielectric constant of 4.0 to 4.5 at 1 MHz, these materials are well-suited to applications where high-frequency electrical performance is vital, such as those in electronic devices. Electrical charge can also leak from one component to another, while the resistivity of the material comes in and strong barrier of electrical charge leakage is particularly important in making reliable and safe electronic circuits.

Resistance to Heat withstanding and Durability

FR4 is characterized by impressive thermal resistance. The FR4 material is designed to operate continuously at temperatures up to 130 °C. This feature is particularly crucial for PCBs used in high-heat-generating electronics, as it protects the PCB during high-temperature operation. Its hardness and low-moisture-resistant property enhance its longevity; hence may last you very long even when exposed in very hard environmental conditions.

Versatility in Applications

Some of the applications of this FR4 material are shown as:

Product Example — Indian Market Consumer Electronics (used in smartphones, TVs, Home Appliances) — Require High Consistency in performance & Safety.

Automotive: It has high thermal stability and durability which are demand for under-the-hood applications in automotive electronics.

AerospaceZone of application: This is a critical area in aerospace electronics where one needs the same material integrity and performance at extreme temperatures.

Military and Defense — Selected for military-grade equipment due to its durability and dependability in extreme conditions.

Cost-Effectiveness

In addition to these advantages, FR4 material is also affordable which makes it a common choice for mass production of PCBs. This is a part of what makes it have such a low cost, as the material is inexpensive and capable of being easily machined in a variety of shapes and sizes. For a competitive manufacturers in electronics market, this cost benefit is quite significant as they wish to save costs and ensure best quality.

Environmental Considerations

The FR4 material is not just popular because of its outstanding performance but also excellent environment sustainability. Matters such as halogens harmful to the environment is not contained, and it meets major environmental standards around the world, including RoHS and REACH.

To learn more about the characteristics of, as well as the applications of fr4 material, check out more information. Its massive application potential speaks of its reliability as well as the importance of this material in the world of electronics manufacturing today.